Fencing Part 2

Keep bovine out of Building zone

In early April, we began planning to erect the first line of fencing in preparation for locking up the cattle once the house build commences. Initially, we contemplated hiring someone else for the task. However, considering the rough plans indicated approximately 2 kilometers of fencing, we opted to tackle the project ourselves. Fortunately, we were fortunate to have a knowledgeable friend experienced in fencing who generously offered to assist us.

We determined that securing the front paddock would be the priority since the trough had recently been relocated there, and it was requiring fencing on only one side. Making some adjustments to our initial plans, we opted for a straight line of fencing. Below is an aerial view indicating the red line, which denotes the fence line we needed to install.

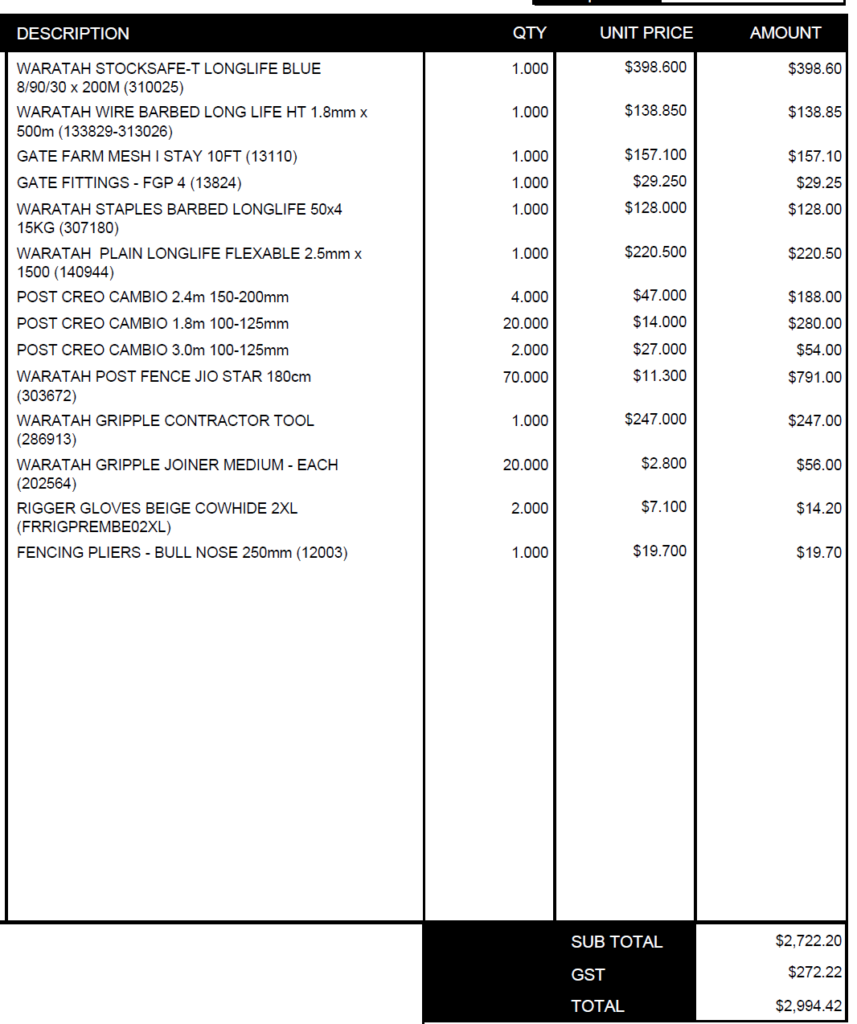

Cost of materials.

In the pervious post (Fencing Part 1) I mentioned we choose to purchase a hydraulic post hole digger for the tractor, this costed us $3,495.45. We then needed to purchase the fencing materials.

We visited our local Ag supply store seeking advice. They suggested spacing wooden posts approximately 10 meters apart, interspersed with star pickets at even intervals, for a stock-safe fencing setup. Additionally, they recommended adding two lines of barbed wire on top to deter rubbing against the posts. Given that our fence line was nearing 200 meters in length, we decided to install two farm gates—one at the top of the paddock and another at the bottom.

While this project incurred significant expenses, as indicated in the invoice below, some of the materials purchased are sufficient for multiple fence lines.

The Process

We aimed to finish the fencing before the Easter long weekend. However, we didn’t start until Saturday, April 13. The Ag store promptly delivered all the items to the property the day after ordering, and the Tractor store also delivered the Post hole digger before the Saturday.

Day 1

At 8am, we were ready to begin. After marking out the line and positions for each wooden post, we laid them out and attempted to connect the tractor. However, we realized that the Post hole digger delivered had the wrong locks—they were too fat to fit onto our tractor. Since it was the weekend and the tractor store was closed, we hurried to the local fodder store, only to find they were sold out. We then decided to check the neighboring town’s fodder store, but due to heavy holiday traffic, we called ahead. Luckily, they had some in stock, so we braved the congested roads and arrived back on site by 10:30am. By then, our mate had let himself in and had already started digging a hole by hand. So lanky grabbed the tractor connected up the digger and got to work.

The basics to putting up a fence, dig the hole – empty the hole – put in the post, back fill poking the soil to remove any air pockets, after you get halfway backfilled you start compressing the soil to make it hard for the post to move. all the while keeping the post level and inline with the past post and future posts.

By the end of day 1 we had half the posts in the ground.

Day 2

Our initial intention was to depart for our holiday either Sunday night or early Monday morning, but our ambitious plans did not materialize. On the second day, time seemed to accelerate, a phenomenon typically experienced when one is thoroughly enjoying themselves. Although nothing went awry, time slipped away swiftly. We successfully completed installing the last of the posts and finished constructing the gate enclosures (we used a box assembly). Later, we relished the evening spectacle of the sun setting while the cows amusingly used the tractor as a scratching post.

Day 3

We decided to only do a half day as we needed to get on the road for the planned holiday. We choose to put up the fencing wire, 1 string of barbed wire and leave the gates till just before the builders come on site and the star pickets for when we got back from NSW. If we weren’t back in time for the builders our mate would hang the gates and lead the cattle in for us. as a result we finished up at around 2pm and headed off to NSW.

We did encounter an issue which was that the fodder store had sold us medium tension wire not high tension, we managed to make the medium tension work but might need to re do it at some point.

Back from NSW

Now that we are back from NSW our plans are to go finish the fence off by installing the last barbed wire, hanging the gates and hammering in the star pickets. we will be meeting the supervisor on site on Monday so will hopefully have trucks attending the property not long after that.